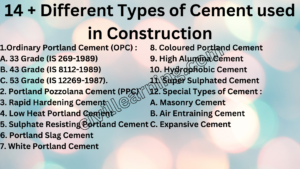

14 Different types of cement as per the the Bureau of Indian Standard (BIS):

- Ordinary Portland Cement (OPC) : 33 Grade (IS 269-1989), 43 Grade (IS 8112-1989) and 53 Grade (IS 12269-1987).

- Portland Pozzolana Cement (PPC) : IS 14890-1991 (Part 1 and Part 2)

- Rapid Hardening Cement (IS 8041-1990)

- Low Heat Portland Cement (IS 12600-1989)

- Sulphate Resisting Portland Cement (IS 12330-1988)

- Portland Slag Cement (IS 455-1989)

- White Portland Cement (IS 8042-1989)

- Coloured Portland Cement (IS 8042-1989)

- High Alumina Cement (IS 6452-1989)

- Hydrophobic Cement (IS 8043-1991)

- Super Sulphated Cement

- Special Types of Cement A. Masonry Cement B. Air Entraining Cement C. Expansive Cement

Ordinary Portland Cement (OPC)

Portland cement is manufactured by pulverising calcareous material and argillaceous material in the right proportion. It is known as O.P.C (Ordinary Portland Cement) and is a common type of cement.

There are three grades of O.P.C (Ordinary Portland Cement).

- OPC-33 grade (IS: 269-989)

- OPC-43 grade (IS: 8112-1989)

- OPC-53 grade (IS: 12269-1987)

The number 33,43 and 53 indicates characteristic compressive strength achieved after 28 days of curing.

Ordinary Portland Cement (O.P.C) is used in general civil construction where there is no sulphate attack and no in underwater concrete.

Portland Pozzolana Cement (PPC)

Portland Pozzolana Cement (PPC) is special blended cement which can be manufactured by grinding together a clinker of cement and pozzolanic material with the addition of gypsum. The mixing ratio of pozzolana may range from 15% to 35% by weight of the clinker.

Pozzolana reacts with calcium hydroxide and water in the hydration process and produces cementitious compounds (C-S-H, gel). This is called pozzolanic action. For example,

Ca(OH)2 + Pozzolana + Water = C-S-H (Gel)

Examples of pozzolanic materials are fly ash (IS 1489 Part 1 of 1991) and calcined clay (IS 1489 part 2 of 1991).

Fly ash is a byproduct produced in a thermal power station when coal is used as a fuel.

Portland Pozzolana Cement (PPC) is used in mass concreting and marine and hydraulic structure because it produces low heat of hydration and gives good resistance to water impurities attacks.

Rapid Hardening Cement (RHC)

Rapid Hardening Cement (RHC) is finer than Ordinary Portland Cement (OPC).

This cement contains less C2S and more C3S than the Ordinary Portland Cement (OPC). This cement rapidly becomes hard as compared to Ordinary Portland Cement (OPC). The 1 day strength of RHC is equal to 3 days strength of OPC with the same w/c ratio.

Rapid Hardening Cement (RHC) is used to remove shuttering of cement concrete quickly. It saves time as well as money. It is also useful for road projects where there is an urgent need to open the road traffic.

Rapid Hardening Cement (RHC) is more expensive than Ordinary Portland Cement (OPC). The cost of Rapid Hardening Cement (RHC) is 10% to 15% more than Ordinary Portland Cement (OPC).

Low Heat Portland Cement

This cement is basically Portland cement but produced by increasing C2S and decreasing C3S and C3A (more rapidly hydrating compounds).

The heat of hydration of low heat cement is given below as per indian standard specifications.

- The heat of hydration is not more than 65 calories per gm for 7 days.

- The heat of hydration is not more than 75 calories per gm for 28 days.

The extra precaution should be taken during removal of formwork because strength gaining rate is slow.

Sulphate Resisting Cement (SRC)

In this type of cement, the content of C3A and C4AF is low and the content of C3S and C2S is high.

The setting time of sulphate resisting cement (SRC) is the same as Ordinary Portland Cement (OPC). but it has high sulphate resistance. So, it is used in substructures where soil is affected by sulphates, sewage treatment plants and marine structures.

Portland Slag Cement

Portland slag cement is produced by grinding clinkers of portland cement and granulated blast furnace slag. The content of the slag ranges from 25% to 65% by weight of cement.

The strength gain of portland slag cement is slower than ordinary portland cement. So, this cement is suitable for mass concreting but not suitable for cold weather concreting.

Coloured Cement (White Cement)

Manufacturing process of white cement is the same but iron oxide content is limited to 1% and sodium alumino ferrite is added to act as a flux. The grey colour of cement is because of iron oxide presence so iron oxide content is limited to 1%.

The white cement has the same properties of OPC. ISI scale or Hunter’s scale is used to measure whiteness of white cement. The whiteness of white cement should not be less than 70%.

High Alumina Cement (HAC)

High alumina cement has a very different composition from Portland cement. It has good resistance to sulphate attack. It achieves strength quickly and has high heat of hydration. It also resists freezing and thawing actions.

The raw materials used for production of high alumina cement are lime and bauxite (possess high aluminium content).

High alumina cement is more expensive than OPC. It is used where early removal of formwork is required.

Hydrophobic Cement

Hydrophobic cement is manufactured by internal grinding of clinkers of portland cement with 0.1 to 0.4% of water repellant film forming compounds like stearic acid.

Hydrophobic cement reduces cement deterioration during long term storage, long distance transportation etc because the water repellant film created around particles of cement.

Masonry Cement (IS : 3466)

Masonry cement is a mixture of portland cement and hydrated lime to obtain properties like workability, setting times, durability and water retention.

Masonry cement is not suitable for construction work but can be used for masonry work and plastering work.

Air Entraining Cement

Air entraining cement is manufactured by adding an air entraining agent (0.1 to 0.3%) with an OPC clinker during the grinding stage.

Examples of air entraining agents are alkali salts and synthetic detergent. It develops the air bubbles and improves the workability of concrete.

FAQs

Which cement is best for marine structure?

Sulphate Resisting Cement (SRC) is best for construction of marine structure because it has good resistance to sulphate attack.

Which cement is suitable for Road pavement construction?

Rapid Hardening Cement (RHC) is suitable for Road pavement construction because it is provide early strength which is required to open the road traffic.

Which compound is responsible for strength of ordinary portlland cement?

C2S (Di calcium silicate) and C3S (Tri calcium silicate) are 80% of cement content and gives high strength to cement.

You May Also Like – Cement Storage Precautions

You May Also Like – Cement Manufacturing Process

You May Also Like – Different Grades of Cement