Composition of Cement

Cement is a very important binding material for concrete. So, the composition of cement is a very interesting topic for civil engineers. There are 8 main ingredients of cement. The following image represents the 8 main ingredients of cement.

The percentage of cement ingredients are given in the table below.

| Cement Ingredients | Percentage |

| Lime | 60% to 65% |

| Silica | 17% to 25% |

| Alumina | 3% to 8% |

| Magnesia | 1% to 3% |

| Iron Oxide | 0.5% to 6% |

| Calcium Sulfate | 0.1% to 0.5% |

| Sulfur Trioxide | 1% to 3% |

| Alkaline | 0% to 1% |

Functions of Cement Ingredients

Lime :

- Lime is nothing but calcium hydroxide or calcium oxide.

- As per given in above table, lime percentage in cement is 60 to 65%.

- Lime creates aluminates and silicates of calcium.

- Lime is an important ingredient for the strength of cement. Low lime content reduces the strength of cement.In other side, more lime content is cause for expansion of cement.

Silica :

- The chemical formula of silica is SiO2 (Silicon Dioxide).

- As per given in above table, silica percentage in cement is 17 to 25%.

- Silica is an important ingredient because it creates di calcium and tri calcium silicates.

- Silica takes part in the strength of cement.

Alumina :

- The chemical formula of alumina is Al2O3 (Aluminium Oxide).

- As per the above table, alumina percentage in cement is 3 to 8%.

- Alumina takes part in quick setting of cement.

- More alumina content reduces the strength of cement.

Magnesia :

- The chemical formula of magnesia is MgO (Magnesium Oxide).

- As per above table, Magnesia percentage in cement is 1 to 3%.

- Magnesia content should not be more than 3% because excess magnesia content will reduce the cement strength.

Iron Oxide :

- The chemical formula of iron oxide is Fe2O3 (Iron Oxide).

- As per above table, iron oxide percentage in cement is 0.5 to 6%.

- Iron oxide takes part in the colour shade of cement.

- Chemical reaction of iron oxide with calcium and aluminium and creates tricalcium alumino ferrite. This formation takes part in strength and hardness of cement.

Calcium Sulfate :

- The chemical formula of calcium sulfate is CaSO4 (Calcium Sulfate).

- Calcium sulfate is nothing but part of gypsum.

- As per above table, percentage of calcium sulfate is 0.1 to 0.5%.

- Calcucim sulfate retards the setting time of cement and protects the cement against flash set.

Sulfur Trioxide :

- The chemical formula of sulfur trioxide is SO3 (Sulfur Trioxide).

- As per above table, sulfur trioxide percentage is 1 to 3%.

- Sulfur trioxide percentage should not be more than 3%.

- Excess sulfur trioxide content reduces the soundness of cement.

Alkaline :

- As per above table, Alkaline percentage is 0 to 1%.

- Alkaline content should not be more than 1%.

- Excess alkaline content is the cause for efflorescence of cement.

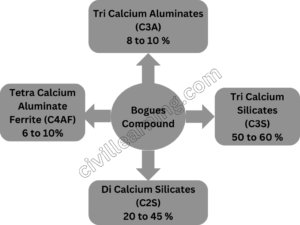

Bogue Compounds of Cement

Bogue compounds of cement are responsible for the hydration process and form the bonds. The Bogue Compounds are given below.

- Tri-calcium Aluminate (C3A)

- Tri-calcium Silicates (C3S)

- Di-Calcium Silicates (C2S)

- Tetra-Calcium Alumino Ferrite (C4AF)

Some roles and percentages of Bogue Compound is listed below.

| Bogue Compound | Chemical Formula | Percentage | Roles |

| Tri-calcium Aluminate (C3A) | 3CaO.Al2O3 | 8 to 12% | It creates early strength and is responsible for rapid hardening. It is also responsible for flash set in cement. |

| Tri-calcium Silicates (C3S) | 3CaO.SiO2 | 50 to 60% | It is responsible for the initial strength of 7 days. |

| Di-calcium Silicates (C2S) | 2CaO-SiO2 | 20 to 45% | It is responsible for lateral strength after 7 days. |

| Tetra-calcium Alumino Ferrite (C4AF) | 4CaO.Al2O3.Fe2O3 | 6 to 10% | It provides grey colour to cement. |

Tri-calcium Aluminate (C3A)

- The chemical formula of Tri-calcium Aluminate is 3CaO.Al2O3. The percentage of this compound is 8 to 12% in cement.

- Tri-calcium Aluminate produces the early strength in cement.

- It is also responsible for rapid hardening in the cement.

- Tri-calcium Aluminate is responsible for flash set in cement because it produce early strength in cement.

Tri-calcium Silicates (C3S)

- The chemical formula of Tri-calcium Silicates is 3CaO.SiO2. The percentage of this compound is 50 to 60% in cement.

- Tri-calcium Silicates creates an initial strength of 7 days.

- It is responsible for rapid hardening. So, rapid hardening cement is used in cold weather concreting.

Di-calcium Silicates (C2S)

- The chemical formula of Di-calcium silicates is 2CaO.SiO2. The percentage of this compound is 20 to 40% in cement.

- It is responsible for lateral strength after 7 days and upto 1 year.

- For example, in low heat cement, lower heat of hydration is required so the ratio of di-calcium silicates is modified.

Tetra Calcium Alumino Ferrite (C4AF)

- The chemical formula of tetra calcium alumino ferrite (C4AF) is 4CaO.Al2O3.Fe2O3. The percentage of this compound is 6 to 10% in cement.

- It does not take part in the strength of cement.

- It also helps to lower the temperature of clinker during cement manufacturing.

- It is responsible for the grey colour of cement.

FAQs

What is the main composition of cement?

Total 8 ingredients of cement. 1)Lime, 2)Silica, 3) Alumina, 4) Magnesia, 5) Iron Oxide, 6) Calcium Sulfate, 7) Sulfur Trioxide and 8) Alkaline.

Why is gypsum added in cement?

Gypsum is added in cement because it controls the setting of cement. It also help to prevent flash set of cement.

What is the Bogue composition of cement?

There are 4 Bogue compounds of cement. 1) Tri-calcium Aluminate, 2) Tri-calcium Silicates, 3) Di-Calcium Silicates and 4) Tetra-Calcium Alumino Ferrite.